Catalog [Hide]

As the industry develops, the number of goods produced increases day by day, storage on the warehouse floor will be extremely messy and easily damaged, as well as loading and unloading goods more difficult. Therefore, choosing the Drive in/Drive through heavy-duty industrial storage racking system will be the solution to the business's storage problem.

Choosing a suitable storage racking system will save space and increase the volume of goods stored in the warehouse, easily managing and controlling inventory.

What are drive in racks?

Drive in/Drive Through racks are a type of racking warehouse system that specializes in storing heavy goods in the industry, used to store unit goods, with the same pallet size, containing large quantities of goods. Optimize space and area for warehouses. Rows of shelves are placed next to each other, thereby reducing warehouse aisles, helping to increase storage space many times over.

What’s the difference between drive-in and drive-through pallet racking?

Depending on the type of load management strategy required, this high-density storage system can be configured in two ways: drive-in or drive-through racking.

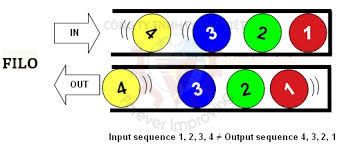

In the first and most common variety, loading and unloading operations are carried out from the same working aisle. Thus, stock is managed following the LIFO (last in, first out) principle.

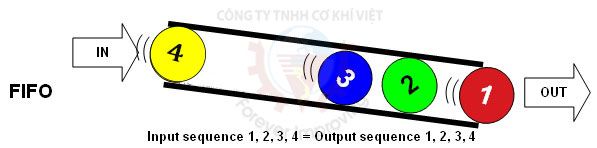

With drive-through storage, on the other hand, pallets are deposited and retrieved in two different aisles: goods go in on one end and are removed from the other. In this case, the loading/unloading sequence is done in line with the FIFO method (first in, first out). This configuration is typically employed when the system is used as a buffer or interim warehouse to effectively regulate flows between two work areas (for example, between production and dispatch or between different manufacturing stages).

Contact for your free consultation:

Benefits of choosing Drive-in racking system

- Low investment costs compared to the throughput achieved.

- Optimizing cost on warehouse space compared to other storage shelves.

- Absolutely optimize space, warehouse area, make use of every m2 in the warehouse into a place to store goods.

- Convenience in the use of forklifts.

- Two solutions "FILO" and "FIFO" can be combined to increase efficiency.

- Storage of bulk goods

- The design is sturdy, durable, meets the standards of load and safety.

Product Description

|

Item |

Value |

|

Product Name |

Drive-in Racking system |

|

Depth |

3-10 pallet |

|

Width |

Customized |

|

Material |

G450, G550, SS400, SS490 High Class Carbon Steel |

|

Package |

Standard Exported Package |

|

Payment Terms |

50% Deposit 50% Balanced |

|

Warranty |

24 Months |

|

Use |

Warehouse Rack |

|

Weight Capacity |

500 - 3000kg |

|

Height |

12m or Customized |

|

Delivery time |

30 days or more depending on quantity |

|

Service |

Customer Designs |

|

Finish |

Hot Dip Gavanized; Powder Coating |

|

Specification |

Warehouse Storage Powder Coating Steel Platform |

|

Certification |

CE |

Why choose us?

Viet Mechanical Co., Ltd - Introducing the supplier of warehouse racking in Vietnam:

Scale production

Factory system of Viet Mechanical with a total area of 11,000 m2 with a full range of advanced machinery systems: Central CNC stamping system with automatic stamping lines, CNC bending machine system, System of automatic rolling machine lines, automatic welding machine system and two automatic electrostatic painting lines.

Manufacturing capacity for storage racks

Viet Mechanical has welcomed many delegations to visit the factory from many different countries such as the US, Australia, Switzerland, Thailand, Cambodia, etc. Through the factory tour process, partners can evaluate the manufacturing capacity, supply capability, as well as modern machinery and equipment, automatic production processes, and packaging systems at Viet Mechanical, ...

The leading manufacturer and exporter of warehouse storage rack in Vietnam:

Geographical position

Cat Lai Port's strategic location and transportation infrastructure make it an ideal gateway for the import and export of goods to and from southern Vietnam, Viet Mechanical believes your orders will be delivered in the short time.

Cat Lai Port is also located close to other major ports in the region, such as Tan Cang - Cai Mep International Terminal (TCIT) and Phu My Port. This proximity allows for efficient transportation of goods by sea and land, which can help shorten the delivery time to customers.

Production standards for storage racks of Viet Mechanical

To meet the export criteria for storage racks, depending on each customer or the regulations of the country, there will be specific requirements for production standards. However, among them, there are some common standards that Viet Mechanical has achieved to meet the demand for exporting storage rack manufacturing for the international market, such as:

- Material Standard JIS (Japanese Industrial Standard): This is one of the leading quality production standards in Japan and is a production standard for the industrial sector in many countries.

- Design Standard FEM 10.02.07 (Federation Europene de la manutention): This is a set of design and safety standards in Europe and provides design rules that incorporate specific characteristics.

- ASTM (American Society for Testing and Materials) paint standard: This is the American paint standard, and the paint materials used by Viet Mechanical meet the highest quality standards for application in the automatic painting line, including some main types such as powder coating, galvanized coating, hot-dip galvanized coating.

- Quality standard ISO 9001:2015: ensure the highest product quality when leaving the factory.

- Input material: SS400 steel, Ensure full certificate of input quality materials.

- Packing: Exported products are pre-packaged with quality export materials such as Corrugated paper, carton box, plastic film, steel tie and air bag... packed into blocks, and transported in containers. The goods inside the container are fixed with straps and shock-absorbing devices to avoid damage during transportation.

VIET MECHANICAL CO.,LTD

- Head office: 8 Street No.20, Ward 11, Disrict 6, Ho Chi Minh City

- Factory: Lot MG4-2 Road No.1, Duc Hoa Industrial Zone, Duc Hoa, Long An Province

- Email: [email protected]

- Hotline for customers international: (+84) 906 672 472 (Tina)

- Website: cokhiviet.net

Download | Viet Mechanical's export racks product leaflet